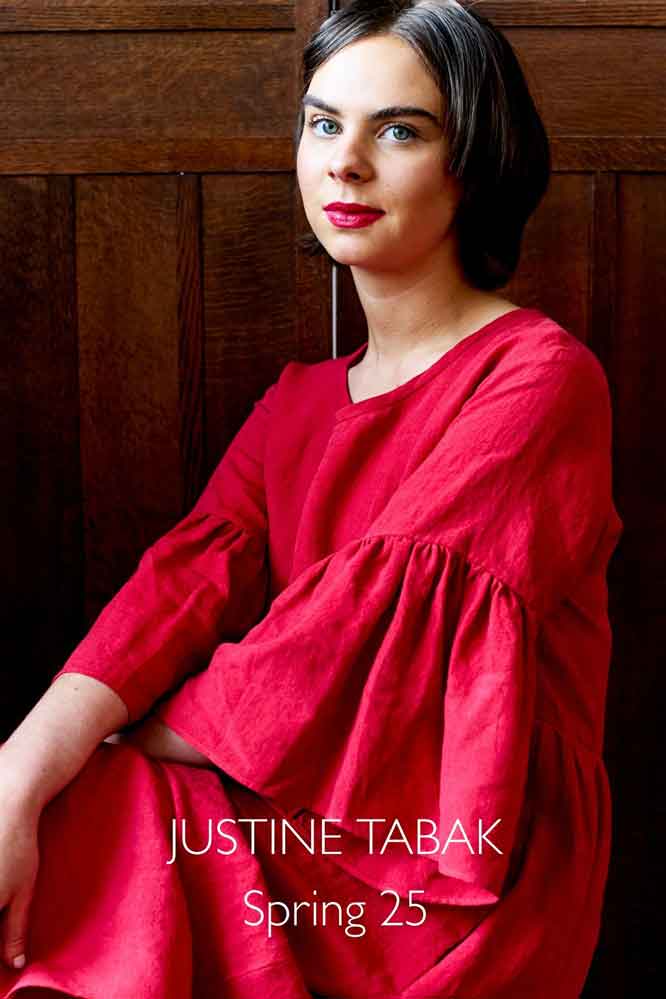

Our Philosophy

I set up Justine Tabak because I wanted to create a fashion business that could operate both ethically and sustainably. In my eyes, fashion should be joyful and life enhancing, a celebration of beauty and creativity and a way each of us can express our individuality without causing harm to the world around us.

Newspaper reports tell us again and again that fashion is one of the most polluting industries in the world, producing mountains of waste and poisonous chemicals. With huge costs to the environment and communities, fast fashion brands reinforce a cycle of cheap production to manufacture mountains of cheap clothes, worn few times and discarded to landfill, marketed with expensive campaigns to reinforce we must have the next latest trend and buy more.

Justine Tabak was established in 2016 with the aim of doing things differently. We became part of the ‘slow fashion’ movement, focusing our efforts into manufacturing small batches of beautifully crafted clothes right here in the heart of London. As far as possible, I source fabrics from the British Isles; when that’s not possible, I revive deadstock material that would otherwise go to waste.

We also design with longevity in mind. Our styles are simple, charming, practical and pretty with a touch of romance thrown in. We hope you find our styles ‘keepers’, the dresses in your wardrobe that you pull out time and again for years to come.

Responsible production

Local manufacturing

The manufacture of textile and clothes was once the single most important industry throughout Britain; this industry helped define the Victorian era and was the driving force for the Industrial revolution. Sadly, by the middle of the twentieth century it had all but disappeared.

In recent years there has been a move to reverse this trend and I’m proud to play a small part of this new creative revolution. I decided to manufacture all my clothes in the UK because I loved the idea of working closely with local communities, supporting local makers, and putting back into the local economy. I didn’t want to have to travel around to world to find people to make my dresses or be compelled to ship fabric and dresses back and forth: what a waste of time and energy not to mention the negative impact that would have on the carbon footprint of a garment! On the contrary, I wanted to manufacture locally, see where my clothes were being made and to get to know the wonderful people who are sewing my designs. Five years on, we have built strong relationships with our partner makers, visiting them weekly and together we have grown a lovely business together.

Batch production

We produce in batches to save waste. Once our dresses have been designed, patterns created, and fabrics selected, we ask our makers to cut and sew in batches throughout the year. By ‘batching’ we control both the quantity and quality of our clothes. The styles are cut with care, in manageable amounts, to avoid fabric waste and to ensure that any flaws in the fabric are avoided (this is particularly relevant with deadstock fabrics). Flaws in fabric simply lead to garments being rejected in quality control thus wasting both material and labour. Small batch production means we don’t carry huge unmanageable stocks, whilst allowing the flexibility to make more quickly responding to demand. It means that we don’t have huge stocks to sell in sales as we don’t overproduce, whilst conversely, we can usually add a few more should you miss out on a favourite style. Contact Elizabeth at support@justinetabak.co.uk to go on any waiting lists.

Responsible fabrics

Here at Justine Tabak we try our hardest to ensure we use responsible sources and conscious credentials. We don’t grow cotton or linen in this country, but we can make sure we use fabrics that have been created with the planet in mind. I love to use natural fabrics in my collections, for their greener credentials and ability to biodegrade back into the environment. Here are some of the fabrics you will see crop up continuously throughout the year:

Linen

We use linen as often as we possibly can. I love it for its natural quality and ease of care for modern life. Linen is not just a luxurious looking fabric, it’s an ecologically remarkable fibre for its regenerative qualities; it grows with rainwater alone and enriches the soil that it's grown in with no need for fertilisers and polluting additives. It's a zero-waste fibre with every part of the plant used in its life cycle and once cropped, flax farming leaves the earth enriched and naturally fertilised. Incredible linen really does the planet good!

Many of our bespoke linens are woven by Stephen and his brother Seamus in their mill in Ireland (pic) Stephen weaves our beautiful linen checks, working with us on our designs and producing 'no-waste' lengths of sustainably made cloth.

Responsibly sourced cotton

We have good relationships with few suppliers so that we can track our cotton qualities and provenance. Cotton is known for high water consumption in its production but there are initiatives to ensure it can be made as consciously as possible. We work with suppliers who support the Better Cotton Initiative and Global Organic Textile Standard (GOTS) and those who are committed to responsible practices. We are continually doing our best to work with suppliers who care for the environment and its communities.

Made in Liberty Eco Viscose

We enjoy using Liberty Fabrics LENZING™ ECOVERO™ Eco Viscose fabric. It is made from EU Ecolabel-certified viscose fibres derived from wood and pulp from responsibly-managed sources, producing up to 50% lower emissions and water impact than generic viscose. With rich colour and clear print definition, this versatile and super-soft dress fabric base is well suited for our flowing tiered dresses.

Made in Cotton Liberty Tana Lawn

We use a lot of Liberty Tana Lawn; this fine cotton lawn is Oeko-tex certified and made in conjunction with the Better Cotton Initiative, a collective movement to promote better cotton farming practices, non polluting dyes, safe for the environment and the customer

Nottingham Lace

I’ve always been fascinated by lace, its delicate nature and wealth of patterns, and always wanted to include lace in my designs. I discovered exactly what I was looking for at the Cluny Lace Company, the last remaining lace maker in England. Owned by the Mason family for nearly 200 years, they have a long history of making distinctive patterns of lace from their vast archives. Their purposely designed factory, built around 1900, is situated on the border of Nottinghamshire and Derbyshire in the heart of the UK. It is a joy to be buying their lace for our dresses, not only is it stunningly beautiful, but we are also delighted to support the tradition of lacemaking in this country.

Scottish knitwear

We are proud to work with makers in Scotland who have a long heritage of creating beautiful fine knitwear. Not only do we support the craft of knitting in the UK, almost all the yarns spun for our knitwear is sourced locally too, keeping the carbon footprint of our knits to an absolute minimum.

When you buy a knitted piece from Justine Tabak, you are buying into a tradition of craft and workmanship that comes from Scottish manufacturing, made with care for the environment with ethical sourcing. We style with longevity in mind, our knits designed to be cherished, and passed on for years to come, always using natural yarns which biodegrade back into the environment.

Many of our knitwear pieces are created ‘in the round’, a process of seam free whole garment knitting where the jumpers are cast off the machines as a complete piece with zero waste.

Deadstock fabric

Deadstock is certainly not a pretty name but by using these remainder fabrics, we are lessening our impact on the environment by making use of beautiful leftovers. What’s more, it’s hugely rewarding to revive and revitalise these fabrics into some of our most beautiful dresses. Due to the nature of deadstock, supply is limited and finite and we sometimes make just ten of each design. So, by its very nature the use of deadstock fabric fits perfectly with our model of batch production and our ‘slow fashion’ ethos: we’re not making too much of any one thing, once it’s gone it’s gone meaning that each dress is a treasure to be kept and worn with pride.

Just around the corner from our studio in Hackney is a warehouse full of deadstock fabric; it is an Aladdin’s Cave of some of the most glorious fabrics I’ve ever seen in my life. Sometimes, I have to clamber over the mountains of ordinary cottons and synthetics to reach the gems, but it is worth it!